What is &Why Need Rapid Prototyping

Rapid prototyping is a process used in product development to quickly create a physical model or prototype of a design concept. It allows designers, engineers, and manufacturers to test and validate their ideas before investing significant time and resources into full-scale production.

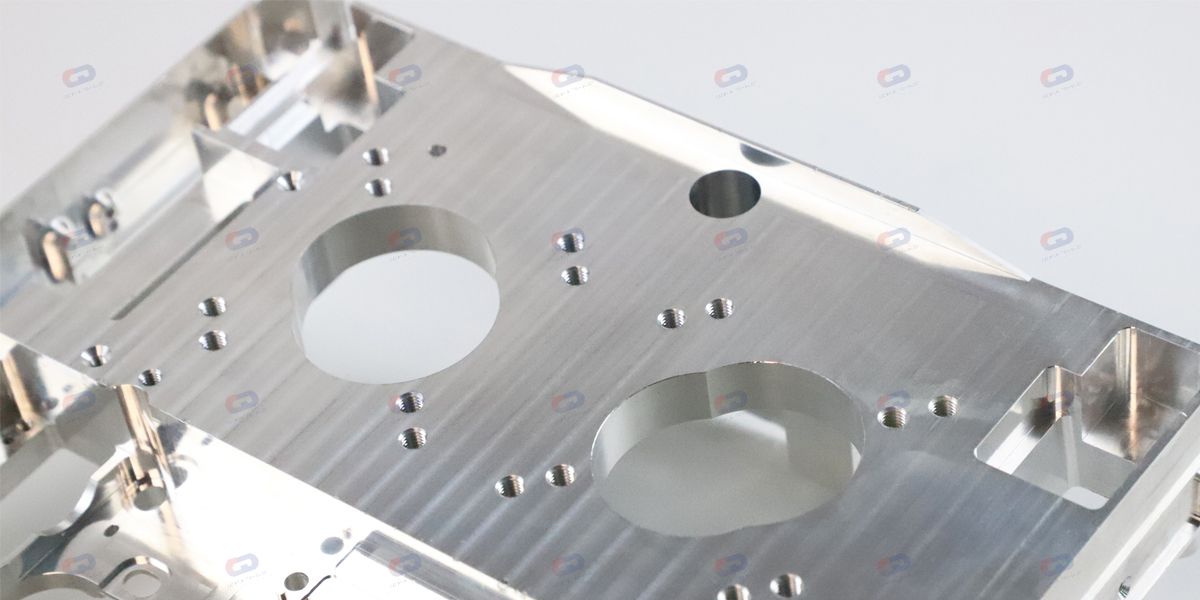

The goal of rapid prototyping is to accelerate the design iteration cycle and reduce development time. It involves using various technologies, such as 3D printing, computer numerical control (CNC) machining, or laser cutting, to fabricate a scaled-down version of the product or component. These technologies can rapidly translate digital designs into physical objects by layering or subtracting material.

By creating a physical prototype, designers can assess the functionality, aesthetics, and ergonomics of their design. They can identify potential flaws, make necessary improvements, and gather feedback from stakeholders or potential users. Rapid prototyping also enables quick modifications and refinements to the design, helping to refine and optimize the final product.

Rapid prototyping facilitates communication and collaboration among team members and stakeholders. The physical prototype provides a tangible representation of the design, making it easier to convey ideas, address concerns, and make informed decisions. This iterative process of prototyping, testing, and refining ultimately leads to the development of a more robust and successful product.

As a leading manufacturer of rapid prototyping, GD-HUB is confident that your design ideas will be transformed into reality.

Is rapid prototyping the same as 3D printing?

The answer is :No, rapid prototyping and 3D printing are not the same, 3D printing is one of the commonly used techniques in rapid prototyping.

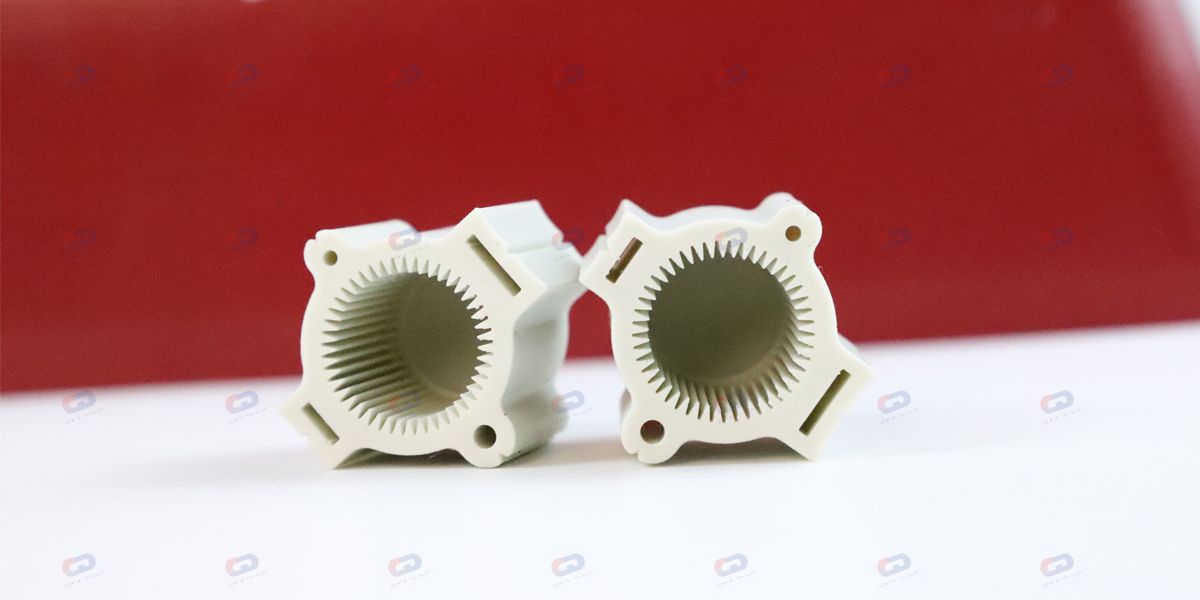

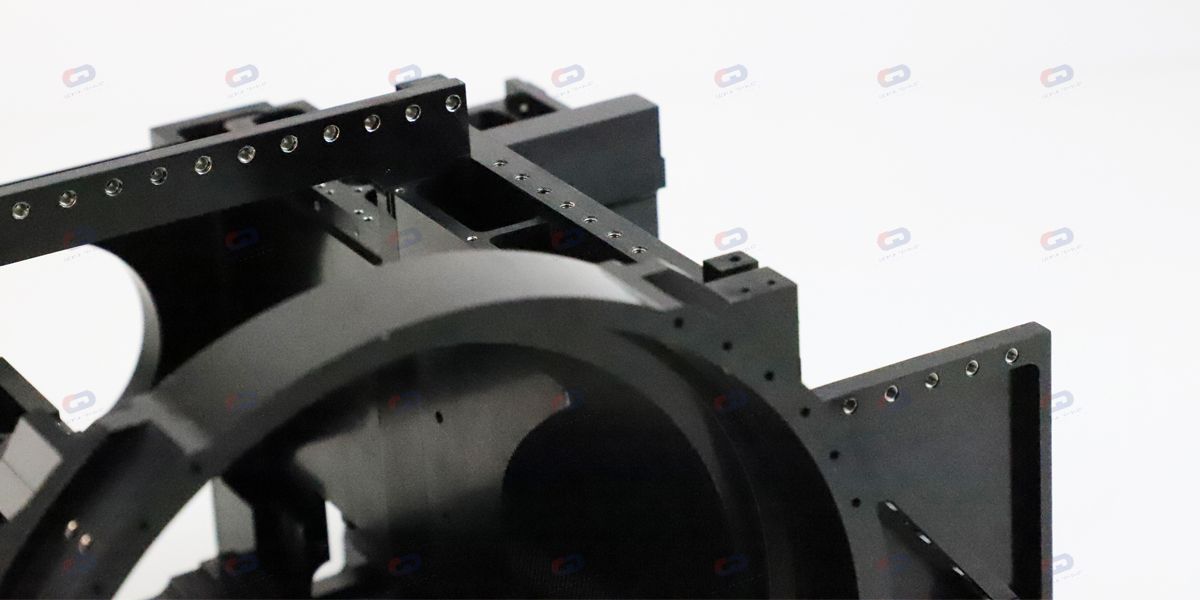

3D printing, also known as additive manufacturing, is a specific technology within the realm of GD-HUB rapid prototyping. It involves creating three-dimensional objects by adding layers of material, typically plastic or resin, based on a digital 3D model. 3D printing allows for the direct conversion of digital designs into physical objects, enabling the rapid production of prototypes with complex geometries.

While 3D printing is widely used in rapid prototyping due to its speed, cost-effectiveness, and ability to create intricate designs, rapid prototyping encompasses a broader range of methods beyond just 3D printing. Other techniques, such as CNC machining, may be preferred for certain projects that require different materials, higher precision, or specific surface finishes. Therefore, while 3D printing is a popular tool in rapid prototyping, it is not the only method used in the process.

How much does rapid prototyping cost?

The cost of rapid prototyping can vary significantly depending on several factors:

Design Complexity: Prototyping intricate or highly detailed designs often requires more time and resources, which can increase costs.

Prototyping Method: The chosen prototyping method affects the cost. Technologies like 3D printing, CNC machining, or injection molding have different associated costs based on the materials used, machine time, and post-processing requirements.

Material Selection: The type and quality of materials used for prototyping can impact the cost. Some materials, such as specialized or high-performance polymers, may be more expensive than standard options.

Size and Quantity: Larger prototypes generally require more material and longer production times, leading to higher costs. Similarly, if multiple prototypes or iterations are needed, the overall cost will increase.

Finishing and Post-Processing: Additional processes like surface finishing, painting, or assembly may be necessary depending on the project requirements. These additional steps can add to the overall cost.

Outsourcing vs. In-house: Whether you choose to outsource the prototyping process or perform it in-house can also affect the cost. Outsourcing may have higher upfront costs but can provide access to specialized expertise and equipment.

Consult with a trusted prototyping service provider or manufacturer to get an accurate cost estimate based on your specific project requirements.