9001:2005

CERTIFICATED

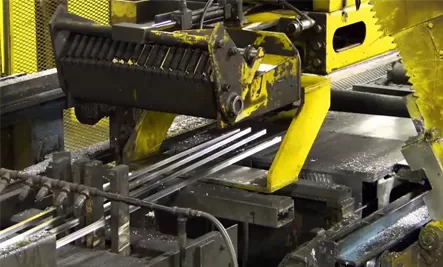

EXTRUSION

MACHINES 60+

EXTRUSION PARTS

MADE MONTHLY 1 MILLION

METAL

ALUMINUM MATERIALS

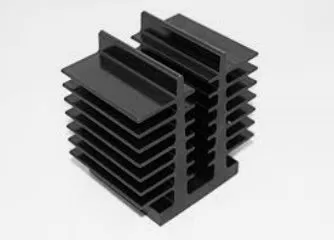

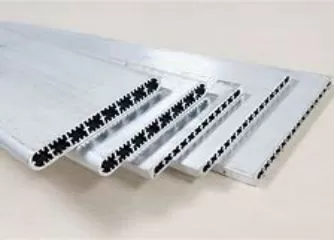

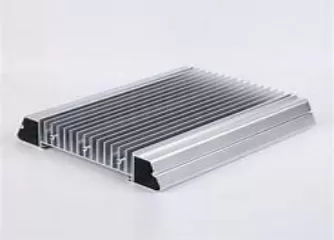

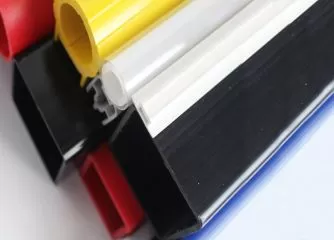

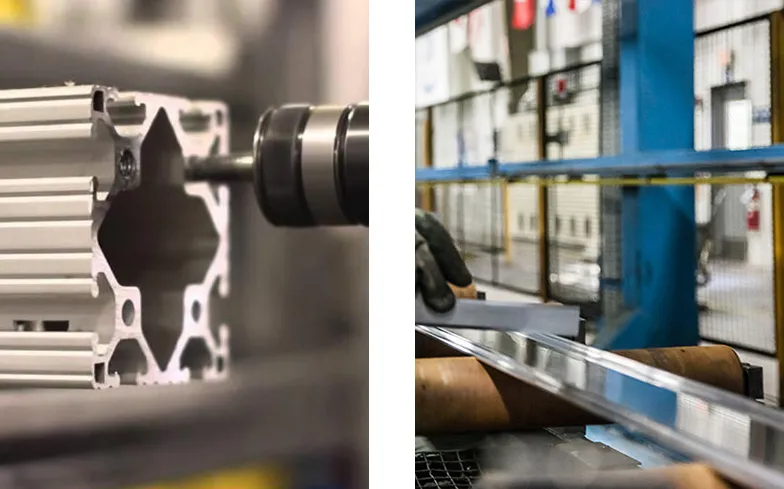

GD-HUB's team of extrusion expertise uses Aluminum extrusion to force aluminum through a die into specific shapes or contours. This process can create complex shapes and designs that are strong, lightweight and durable. Aluminum extrusion service is used in a wide variety of industries, including construction, automotive, aerospace and electronics. The combination of CNC aluminum extrusion can provide an ultra-cost-effective solution for creating complex shapes and designs,providing an excellent strength-to-weight ratio, making it ideal for applications where prototype weight is a concern. Prototype aluminum extrusion is resistant to corrosion and rust, making it a durable choice for outdoor applications, and aluminum extrusions can be easily customized to meet customer-specific lightweighting design requirements. GD-HUB offers a wide range of post-processing options such as:Anodizing, Powder Coating, Painting, Chromate Conversion Coating, Plating and so on, that allow prototype aluminum extrusions to enhance appearance and durability.

Why Choose GD-HUB’s Aluminum Extrusion Service

GD-HUB’s prototype aluminum extrusion services provide custom solutions for a wide range of industries, including construction, automotive, and electronics. If you're looking for a reliable and flexible aluminum extrusion company, GD-HUB is the perfect choice. Unlike other companies that require high minimum order quantities, we offer low volume custom aluminum extrusion and plastic extrusion services, making it easier for you to obtain small batches of prototypes and low Custom Aluminum Extrusion Cost. We also provide one-stop post-finishing services, ensuring that your project is completed to your exact specifications. At GD-HUB, we take quality seriously and conduct rigorous checks on every prototype before shipping, so you can trust that your project is in best manufacturer hands.

ISO certified

ISO certified

Low Volume

Low Volume

Extrusion Parts with Tight Tolerances (Tolerances up to ±0.005)

Extrusion Parts with Tight Tolerances (Tolerances up to ±0.005)

24H/7d Engineering Support

24H/7d Engineering Support

Fast Delivery: 3-7 days (Depending on your project)

Fast Delivery: 3-7 days (Depending on your project)

Capabilities of GD-HUB Aluminum Extrusion

GD-HUB's aluminum extrusion capabilities are among the leading in the industry. Our aluminum extrusion services provide custom solutions for a wide range of industries. Our extrusion process is combined with other manufacturing processes to create more complex shapes and designs that meet your exact specifications. Our team of experts provides 24/7 technical support to understand your needs and design a solution that fits your unique requirements.

Low Volume

Most extrusion companies set very high MOQs, but GD HUB doesn’t.

Low-volume is one of our advantages, no matter One-off prototype extrusions or a few hundred units, GD HUB can help you a lot!

Tight tolerances

GD-HUB's prototype aluminum extrusion produce parts with tight tolerances, ensuring precise dimensions and consistent quality across large production runs.

Customization

GD-HUB's extrusion service also allows for a high degree of customization, we can vary parameters such as material composition, shape, size, color, and finish to meet your parts specific requirements.

Processable Materials

GD-HUB offers an aluminum extrusion service that is compatible with a variety of materials, including aluminum (such as Aluminum 6061 and 6063). To determine if we have a material that meets your prototype project needs, please refer to our material list or contact us directly to discuss your unique requirements. It's important to note that the specific materials that can be processed through extrusion molding depend on factors such as melting point, viscosity, and flow properties. Therefore, careful consideration must be given to the design of the extrusion prototype and processing conditions to achieve the desired results.