9001:2005

CERTIFICATED

CNC/EDM MACHINES

MACHINES 80+

INJECTION MOLDING

MADE MONTHLY 100+

MATERIALS

PLASTIC&METAL 100+

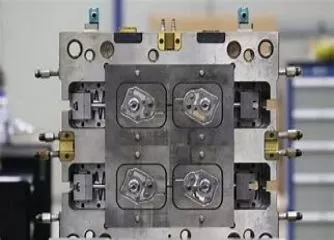

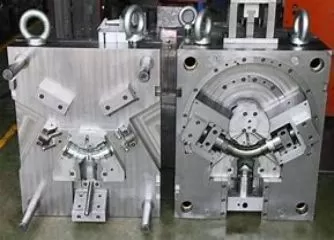

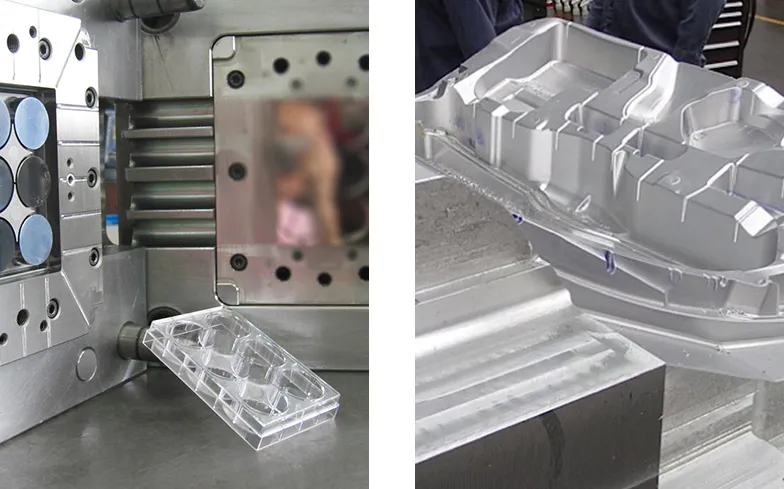

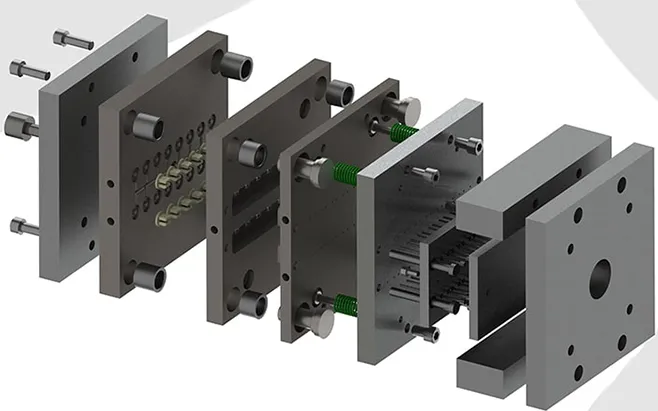

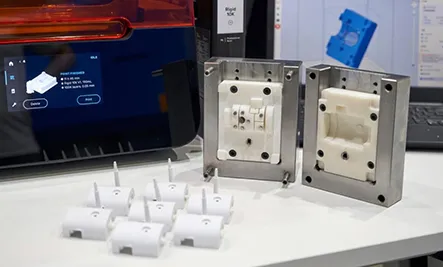

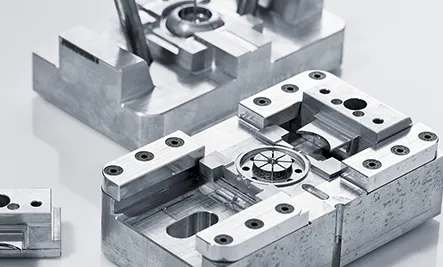

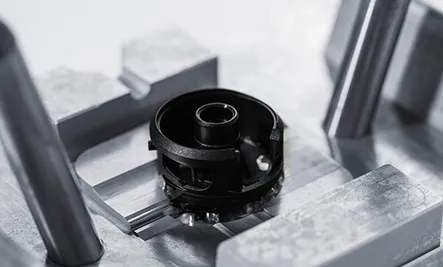

At the core of injection molding lies injection mold tooling, which is responsible for creating the mold into which molten plastic is injected to produce a product or part. The mold itself is usually crafted from either steel or aluminum, and the quality of the tooling design plays a crucial role in determining the overall quality of the injection molding process and the resulting parts. Whether you require a simple or complex application, GD-HUB offers personalized rapid injection mold tooling services to help you create mold that meet your specific needs, from mold design to manufacturing.

Why Choose GD-HUB’s Injection Mold Tooling

GD-HUB's injection molding tooling services are created to meet the unique needs of your project. Our team of experts is available 24/7 to ensure the success of your project. We use the most advanced technology to design and develop precise injection molds and produce your injection molded parts with the highest quality injection mold and speed to allow you to quickly match the market and take the lead. Choose GD-HUB for your rapid injection molding needs and experience the custom service differences.

ISO certified

ISO certified

More Efficient

More Efficient

24H/7d Engineering Support

24H/7d Engineering Support

Leading quality inspection and testing

Leading quality inspection and testing

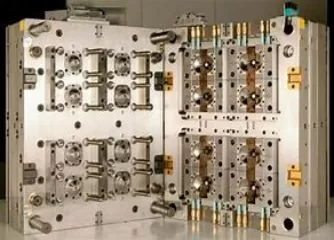

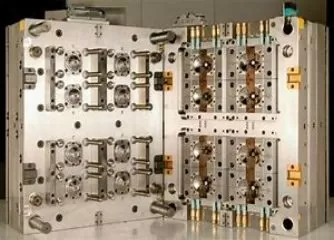

Capabilities of GD-HUB Injection Mold Tooling

GD-HUB is committed to customizing the best quality molds for your injection molding. Our molds are made of durable tool steel materials, ensuring that they will produce hundreds of thousands of parts over their lifetime. We understand that every project is unique, and that's why our custom mold service exists with the mission of doing everything to meet your specific needs. And custom mold service means we can create a mold that perfectly matches the size, shape, and other specifications of your injection molded product, bringing unparalleled precision and accuracy to your high-volume prototype production. Trust us with customization capabilities that exceed your expectations.

Tailored to specific needs

Custom injection molds are designed and built to meet the unique requirements of a particular product. This means that they can be tailored to the specific size, shape, and other specifications of the product, resulting in a higher level of precision and accuracy.

Cost-effective for large volume production

Custom molds are a cost-effective solution for large-volume production runs. While the initial cost of designing and building a custom mold may be higher than purchasing an off-the-shelf mold, the per-unit cost of production will be significantly lower.

Faster production time

Custom injection molds can be designed and built more quickly than ever before. Thanks to advances in computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. This means that your products can be brought to market faster, giving companies a competitive advantage.

Processable Materials

GD-HUB offers custom injection mold tooling services that can work with a variety of materials, including P20 steel, S136, S718, S50C, NAK80, H13, and Aluminum

To determine if we have a material that fits your prototype project needs, please review our materials list or contact us directly to discuss your specific requirements.