Introduce

The semiconductor industry is involved in the design, fabrication, and manufacturing of semiconductor devices, primarily based on silicon wafers. These devices play a crucial role in various electronic applications and are the building blocks of modern technology.

Precision manufacturing plays a critical role in the semiconductor industry due to the microscopic scale and intricate nature of semiconductor devices. The precision required in the manufacturing processes is essential for creating reliable and high-performance semiconductor components.

What is semiconductor industry?

The semiconductor industry is a sector of the electronics industry that focuses on the design, development, and production of semiconductor devices. Semiconductors are materials with electrical conductivity between that of conductors and insulators. The industry is crucial to modern technology as semiconductor devices serve as the fundamental building blocks of electronic circuits and are integral to a wide range of electronic devices.

Key components and activities within the semiconductor industry include:

The industry produces various semiconductor devices, including integrated circuits (ICs), microprocessors, memory chips, sensors, and power devices. These devices are used in everything from computers and smartphones to automotive systems and industrial equipment.

Manufacturing Process:

The semiconductor manufacturing process involves several complex steps, including designing electronic circuits, creating masks, using photolithography to transfer patterns onto silicon wafers, etching to remove excess material, doping to introduce specific electrical properties, and layering to build up the final structure.

The importance of precision manufacturing in semiconductor industry

Precision manufacturing contributes to the improvement of reliability and yield in semiconductor production. Minimizing defects and ensuring consistency in the manufacturing processes enhance the overall quality and performance of semiconductor devices.

Miniaturization and Nanoscale Features:

Semiconductor devices are characterized by incredibly small components and features, often measured in nanometers. Precision manufacturing is essential to create these intricate structures accurately. The ability to manufacture at such a small scale enables higher transistor density and improved performance in integrated circuits.

Performance and Reliability:

The precision in manufacturing processes directly influences the performance and reliability of semiconductor devices. Small deviations or imperfections in the fabrication process can lead to electrical inefficiencies, reduced speed, or even device failure. Achieving precise dimensions and material characteristics is crucial for meeting performance requirements.

High-Volume Production:

The semiconductor industry often operates on a massive scale to meet global demand for electronic devices. Precision manufacturing enables consistent and reproducible fabrication processes, ensuring that large quantities of high-quality semiconductor components can be produced efficiently and reliably.

Advanced Technologies and Materials:

Precision manufacturing is essential for working with advanced materials and technologies. As semiconductor technology advances, the industry incorporates new materials and manufacturing techniques. Precision is critical when handling materials with specific electronic properties, ensuring the successful integration of these materials into semiconductor devices.

Optical Lithography and Advanced Techniques:

Optical lithography is a key process in semiconductor manufacturing, where patterns are transferred onto silicon wafers. Advanced techniques like extreme ultraviolet (EUV) lithography require exceptional precision to achieve smaller feature sizes. The ability to accurately define these patterns is vital for creating complex and high-performance circuits.

Yield and Cost Efficiency:

Precision manufacturing contributes to higher yields in semiconductor production. Minimizing defects and variations in the manufacturing process leads to increased production efficiency and reduced waste. This, in turn, improves the overall cost efficiency of semiconductor manufacturing.

Quality Control and Testing:

Precision is crucial in quality control and testing processes. Rigorous testing of semiconductor devices ensures that only high-quality components reach the market. Precision in testing methods allows for the identification of subtle defects that might impact the functionality and reliability of the devices.

Innovation and Moore's Law:

The semiconductor industry is driven by innovation, and precision manufacturing is a key enabler of this innovation. Advancements in precision allow the industry to adhere to Moore's Law, which predicts the doubling of transistor density approximately every two years, leading to continuous improvements in device performance.

The semiconductor industry common applications in life

1. Integrated Circuits (ICs):

Integrated circuits are the heart of the semiconductor industry. They consist of miniaturized electronic components such as transistors, resistors, and capacitors fabricated on a single chip of semiconductor material.

2. Microprocessors and Microcontrollers:

These are specialized integrated circuits that act as the brain of electronic devices. Microprocessors are used in computers, while microcontrollers are found in everyday devices like washing machines, microwave ovens, and automotive systems.

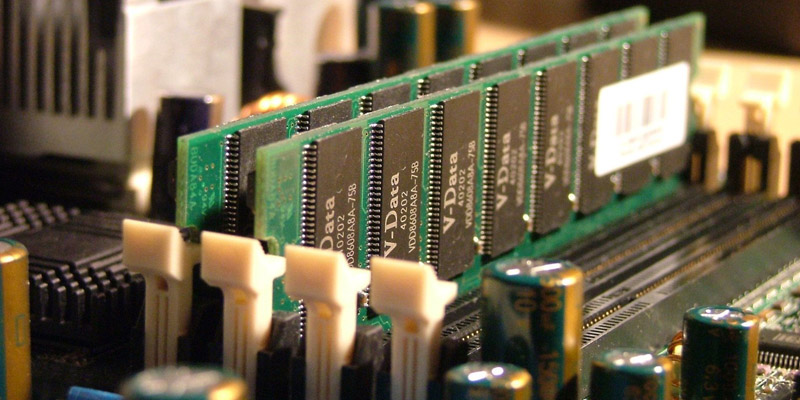

3. Memory Chips:

Semiconductor memory chips, including RAM (Random Access Memory) and ROM (Read-Only Memory), are essential components in computers, smartphones, and other electronic devices for storing and retrieving data.

4. Power Semiconductor Devices:

Power semiconductors, such as diodes and transistors, are used in power electronics applications. They are crucial for power conversion and control in devices like power supplies, inverters, and electric vehicles.

5. Sensors:

Semiconductor-based sensors, like accelerometers, gyroscopes, and temperature sensors, are widely used in smartphones, wearables, automotive systems, and industrial applications for gathering data and enabling various functionalities.

6. Communication Devices:

Semiconductor devices play a vital role in communication technologies, including RF (Radio Frequency) chips, Wi-Fi modules, and cellular communication chips used in smartphones, routers, and other wireless devices.

7. LED and Display Technologies:

Light-emitting diodes (LEDs) and display technologies rely on semiconductor materials. LEDs are used for lighting, while display technologies like LCDs (Liquid Crystal Displays) and OLEDs (Organic Light-Emitting Diodes) are integral to TVs, monitors, and smartphones.

The automotive industry heavily relies on semiconductors for various applications, including engine control units, navigation systems, safety features, and entertainment systems.

Semiconductors are used in medical devices such as imaging equipment, sensors, and diagnostic tools, contributing to advancements in healthcare technology.

10. Internet of Things (IoT):

- The proliferation of IoT devices is driven by semiconductor technology. These devices, ranging from smart home devices to industrial sensors, rely on tiny and efficient semiconductor components.

Summaries

Precision manufacturing is the backbone of the semiconductor industry. The industry's ability to create increasingly smaller and more powerful semiconductor devices relies heavily on advancements in precision manufacturing techniques and technologies. The pursuit of precision is a driving force behind the continuous evolution and innovation in semiconductor manufacturing.

How does GD-HUB's precision manufacturing meet the needs of the semiconductor industry?

We offer the following precision manufacturing services: high-precision CNC machining, extrusion molding, injection molding, overmolding, insert molding, vacuum casting, die casting, rapid 3d printing, sheet metal fabrication, and surface finishing treatments for a wide range of materials.

Some of the key properties of GD-HUB engineering plastics also enable them to meet these challenges. Semiconductor plastics we process:

-Standard materials for enclosures

-Resistant to a wide range of temperatures and chemicals

-Perform well in the rigors of ESD and ultra-high purity applications

-Maintain tight dimensional tolerances over a wide range of temperature fluctuations

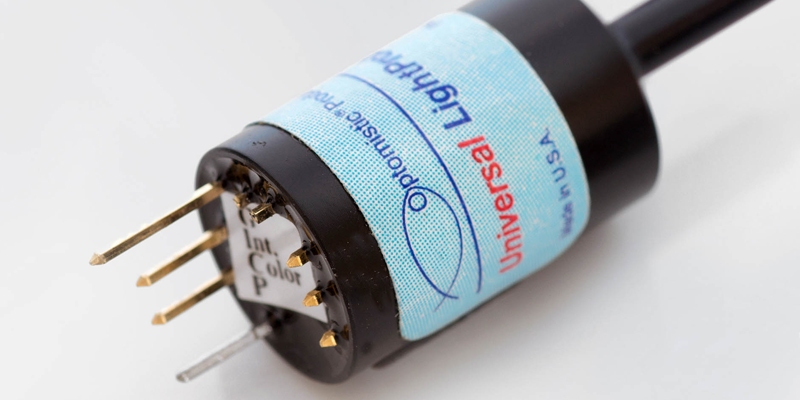

The use of specialty plastics in test sockets, insulators, handling trays, chip pickup holders, screws, washers, spacers, housings and other components can have a significant impact on equipment productivity.

Contact GD-HUB to Advance Your Semiconductor Project.