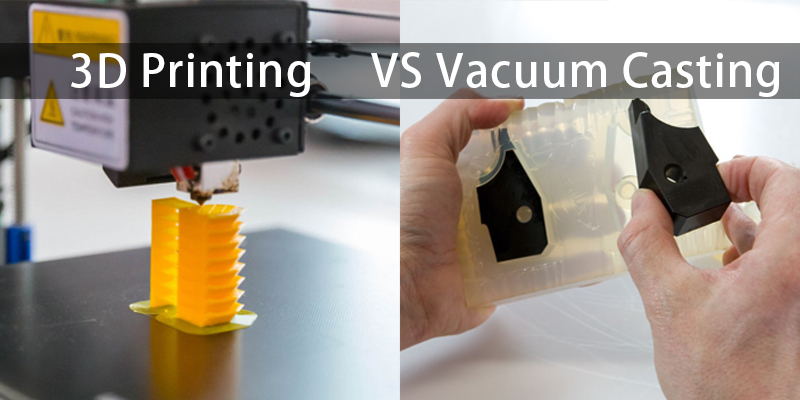

Ⅰ. Vacuum casting and 3D printing

Vacuum casting and 3D printing are two distinct manufacturing processes used for creating prototypes, small production runs, and custom parts. Each method has its own advantages and applications.

1. Vacuum Casting:

Vacuum casting, also known as urethane casting or silicone molding, is a versatile and cost-effective technique for producing small to medium batches of parts or prototypes.

How the process works:

Master Pattern: A master pattern or prototype part is created using various methods such as CNC machining, 3D printing, or traditional sculpting. This master pattern is typically made from a material like plastic or metal.

Silicone Mold: A silicone mold is then created around the master pattern. This mold captures all the intricate details and features of the master pattern.

Vacuum Casting: Liquid resin or polyurethane material is poured into the silicone mold. The mold is placed in a vacuum chamber to remove any air bubbles and ensure the material fills the mold completely.

Curing: The resin is allowed to cure and harden within the mold.

Demolding: Once the resin has hardened, the silicone mold is opened, and the cast part is removed. The mold can be reused to create multiple copies.

2. 3D Printing:

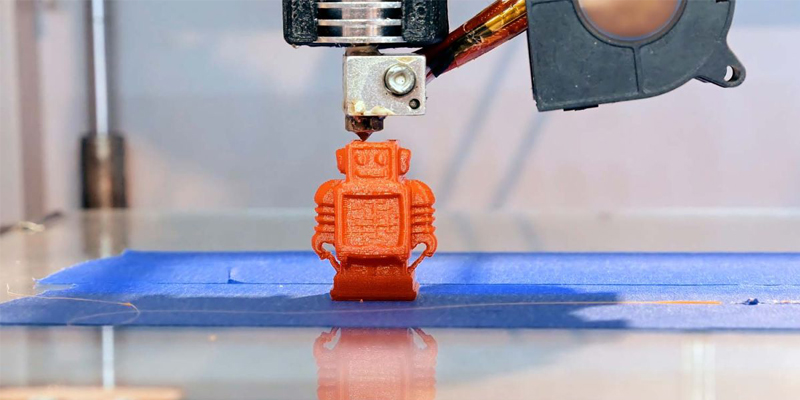

3D printing, also known as additive manufacturing, is a process where a digital design is turned into a physical object by adding material layer by layer.

How it works:

Digital Design: A 3D computer-aided design (CAD) model is created or obtained.

Printing: The 3D printer interprets the digital design and adds material layer by layer to create the physical object. There are various 3D printing technologies, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), etc.

Post-processing: Depending on the technology and material used, post-processing steps like cleaning, sanding, and painting may be required to achieve the desired finish and functionality.

Ⅱ. Main compare with vacuum casting and 3d printing

1. Materials:

Vacuum Casting: Vacuum casting typically uses polyurethane resins, which come in a variety of colors and can mimic the properties of various plastics and rubber. This method offers a wide range of material options.

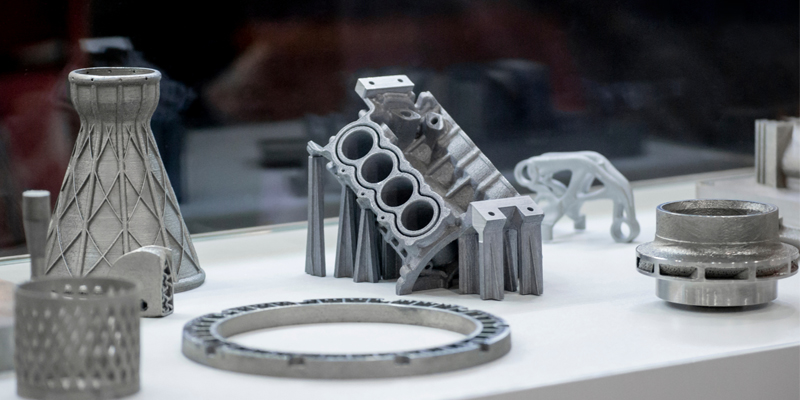

3D Printing: 3D printing can use a diverse range of materials, including plastics (PLA, ABS, etc.), metals (aluminum, titanium, etc.), ceramics, and even some composites. Material choices depend on the specific 3D printing technology used.

2. Speed and Lead Time:

Vacuum Casting: Vacuum casting is generally faster than traditional manufacturing methods like injection molding. It can produce multiple copies of a part in a matter of days or even hours, making it suitable for rapid prototyping and small production runs.

3D Printing: 3D printing is known for its quick turnaround time, especially for prototyping. It's capable of producing parts within hours to days, depending on the complexity and size of the design.

3. Surface Finish:

Vacuum Casting: Vacuum casting typically results in parts with a smooth and high-quality surface finish. Details and textures from the master pattern are faithfully reproduced in the cast parts.

3D Printing: The surface finish of 3D printed parts can vary depending on the technology and settings used. Some 3D printing methods may require post-processing to achieve a smoother finish, especially for intricate or complex designs.

4. Design Complexity:

Vacuum Casting: While vacuum casting can replicate intricate details, it may not be as suitable for extremely complex or geometrically challenging designs compared to 3D printing.

3D Printing: 3D printing excels in creating complex and highly customized geometries, including parts with internal voids and structures that would be difficult or impossible to produce using traditional methods or vacuum casting.

5. Cost:

Vacuum Casting: Vacuum casting can be cost-effective for small to medium production runs but may involve higher initial setup costs due to mold creation. The cost per part decreases as the batch size increases.

3D Printing: 3D printing is cost-effective for prototyping and small-batch production since it doesn't require expensive molds or tooling. However, the cost can increase with larger quantities.

6. Strength and Material Properties:

Vacuum Casting: The strength and material properties of vacuum-cast parts depend on the chosen polyurethane resin, which can be tailored to meet specific requirements. However, they may not match the properties of engineering-grade plastics or metals.

3D Printing: Material properties vary depending on the 3D printing material chosen. Some materials, such as certain metals and high-performance plastics, can offer properties close to or matching those of traditional manufacturing methods.

Ⅲ. Compare Working Principle of Vacuum Casting & 3D Printing

Working Principle of Vacuum Casting:

Master Pattern Creation: The process begins with the creation of a master pattern or prototype part. This master pattern can be made using various methods, including CNC machining, 3D printing, or traditional sculpting. The master pattern represents the part you want to replicate.

Silicone Mold Preparation: A silicone mold is created around the master pattern. The silicone mold captures all the details and features of the master pattern, and it can be made in two parts (a top and a bottom) to facilitate the casting process.

Vacuum Chamber: The silicone mold is placed inside a vacuum chamber. This chamber is used to remove air bubbles from the mold and create a vacuum environment.

Pouring Resin: Liquid resin or polyurethane material is poured into the silicone mold while it is in the vacuum chamber. The vacuum helps to eliminate trapped air and ensures that the resin fills the mold completely.

Curing: The resin is allowed to cure and harden within the silicone mold. The curing time can vary depending on the specific resin used and the desired properties of the final part.

Demolding: Once the resin has fully hardened, the silicone mold is opened, and the cast part is carefully removed. The mold can be reused to create multiple copies of the same part.

Working Principle of 3D Printing:

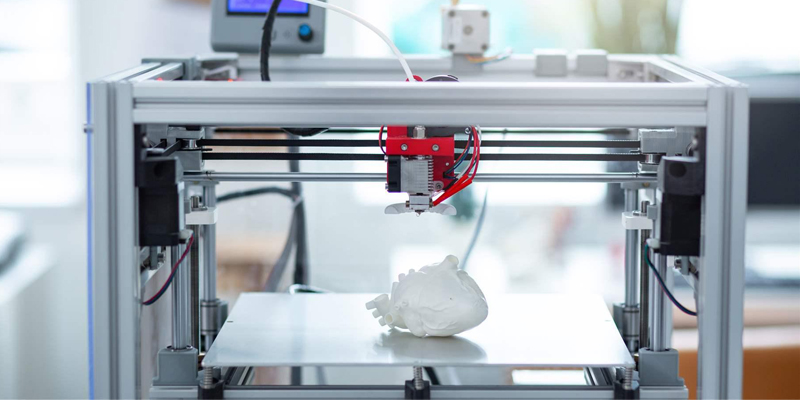

Digital Design: The process begins with the creation of a 3D digital model of the part using computer-aided design (CAD) software. This digital model defines the geometry of the part.

Slicing: The 3D model is sliced into thin horizontal layers using slicing software. These layers serve as instructions for the 3D printer, guiding it on how to build the part layer by layer.

Printing Process: The 3D printer interprets the sliced design and begins building the physical object layer by layer. The printer adds material, whether it's plastic filament, metal powder, resin, or other materials, according to the instructions from the slicing software.

Layer Bonding: Each layer of material is fused, solidified, or adhered to the layer below it. The bonding process varies depending on the 3D printing technology being used (e.g., melting plastic, curing resin with UV light, sintering metal powder with a laser).

Build Completion: The 3D printer continues this layer-by-layer process until the entire part is complete. Depending on the complexity and size of the part, this can take anywhere from a few hours to several days.

Post-Processing: After printing, some 3D-printed parts may require post-processing steps like cleaning, sanding, painting, or assembly to achieve the desired finish and functionality.

Vacuum casting is more suitable for replicating existing parts with high surface quality, while 3D printing excels at creating complex geometries and rapidly prototyping new designs.

Ⅳ. Compare advantage and disadvantage of Vacuum Casting & 3D Printing

Advantages of Vacuum Casting:

High-Quality Surface Finish: Vacuum casting produces parts with a smooth and high-quality surface finish, making them suitable for aesthetic and functional prototypes.

Material Variety: It offers a wide range of material options, including polyurethane resins that can mimic the properties of various plastics and rubber.

Cost-Effective for Small Batches: Vacuum casting is cost-effective for small to medium production runs without the need for expensive molds or tooling.

Short Lead Times: It can produce multiple copies of a part relatively quickly, often in a matter of days, making it suitable for rapid prototyping and small-scale production.

Details and Textures: Vacuum casting faithfully replicates details and textures from the master pattern, making it suitable for parts with intricate designs.

Disadvantages of Vacuum Casting:

Mold Creation: The initial setup process involves creating a silicone mold, which can be time-consuming and costly for complex designs or large quantities.

Limited Design Freedom: While vacuum casting can reproduce intricate details, it may not be as suitable for extremely complex or highly customized designs compared to 3D printing.

Material Limitations: The material properties of vacuum-cast parts may not match those of engineering-grade plastics or metals, limiting their use in certain applications.

Advantages of 3D Printing:

Design Flexibility: 3D printing excels in creating complex and highly customized geometries, including parts with internal voids and structures that are challenging to produce using traditional methods.

Rapid Prototyping: It offers quick turnaround times, making it ideal for prototyping and iterating designs.

No Tooling Required: 3D printing doesn't require expensive molds or tooling, reducing setup costs and lead times.

Material Versatility: A wide range of materials is available for 3D printing, including plastics, metals, ceramics, and composites, allowing for a variety of functional properties.

Scalability: It can be used for both one-off prototypes and small-batch production, and some technologies are suitable for larger-scale production.

Disadvantages of 3D Printing:

Surface Finish: The surface finish of 3D printed parts can vary, and post-processing may be required for a smoother finish, especially for intricate designs.

Material Limitations: While there's a wide range of 3D printing materials, their properties may not always meet the requirements of certain demanding applications.

Speed for Large Batches: 3D printing can be slower than other manufacturing methods for large production quantities due to the layer-by-layer additive process.

Cost for Large Batches: The cost per part can increase with larger quantities, making it less cost-effective than traditional mass production methods for high-volume production.

Ⅴ. Compare application of Vacuum Casting & 3D Printing

Applications of Vacuum Casting:

Prototyping: Vacuum casting is commonly used for rapid prototyping in industries like product design, automotive, and consumer electronics. It allows for the creation of high-quality prototypes that closely resemble the final product.

Small to Medium Production Runs: It is well-suited for producing small to medium batches of parts, especially when a quick turnaround and cost-effectiveness are required.

Aesthetic and Functional Parts: Vacuum casting produces parts with excellent surface finish and detail, making it suitable for both aesthetic models and functional prototypes.

Customization: Vacuum casting can easily produce customized parts, such as personalized consumer products, medical devices, or promotional items.

Jewelry and Art: It is used in the jewelry industry to create intricate, detailed pieces, as well as in the art world for producing sculptures and art installations.

Applications of 3D Printing:

Rapid Prototyping: 3D printing is widely used for rapid prototyping across various industries, allowing for quick design iteration and functional testing.

Complex Geometries: It excels at creating complex and highly customized geometries, such as lattice structures, lightweight components, and intricate parts with internal voids.

Customization: 3D printing is ideal for producing one-off or customized parts, including personalized medical implants, orthodontic devices, and footwear.

Aerospace and Automotive: It is used in aerospace and automotive industries for producing lightweight, complex components like turbine blades, brackets, and interior panels.

Dental and Healthcare: 3D printing is employed in dental applications for making dental crowns, bridges, and aligners, as well as in healthcare for creating patient-specific medical models and implants.

Educational and Research: 3D printing is widely used in education and research for teaching, experimentation, and the creation of scientific models and prototypes.

Art and Fashion: Artists and fashion designers use 3D printing to create unique sculptures, fashion accessories, and avant-garde clothing designs.

Ⅵ. The choice between vacuum casting and 3D printing depends on your specific project requirements and objectives.

l Choose Vacuum Casting When:

You Need High-Quality Surface Finish: If your project demands parts with a smooth, high-quality surface finish and fine details, vacuum casting is an excellent choice. It can faithfully replicate the surface texture and details of the master pattern.

You Require Multiple Copies of the Same Part: Vacuum casting is cost-effective for producing multiple copies of the same part. If you need a small to medium batch of identical parts, vacuum casting can be more economical than 3D printing.

Customization Is Necessary: Vacuum casting allows for customization and personalization of parts, making it suitable for creating unique or bespoke products that require individualized features.

You Have a Short Lead Time: Vacuum casting can provide relatively quick turnaround times, especially for small production runs. If you need parts within a short time frame, vacuum casting can be a good option.

You're Focusing on Aesthetic Prototypes: When the appearance and visual appeal of the prototype are crucial, vacuum casting can deliver highly aesthetic prototypes with a polished finish.

l Choose 3D Printing When:

You Need Rapid Prototyping: 3D printing is an ideal choice for rapid prototyping. It allows you to quickly produce physical prototypes of 3D digital designs, facilitating the iterative design process.

Complex Geometries Are Required: If your design features complex geometries, intricate internal structures, or lightweight components, 3D printing excels in creating such designs that may be challenging to achieve with other methods.

Customization Is Essential: If you need highly customized parts tailored to specific individual or application needs, 3D printing is a powerful tool for creating one-of-a-kind pieces.

Toolless Manufacturing Is Preferred: 3D printing eliminates the need for molds and tooling, making it a cost-effective choice for one-off or small-batch production without the setup costs associated with traditional manufacturing methods.

You're Focusing on Functional Prototypes: Beyond visual prototypes, 3D printing can produce functional prototypes that can be used for testing and validation of mechanical and functional properties.

Innovation and Design Exploration: If your goal is to innovate and explore new design concepts, 3D printing provides flexibility for experimentation and rapid design iterations.

You Need Diverse Material Options: 3D printing offers a wide range of materials, including plastics, metals, ceramics, and more. This allows you to select materials that match your specific project requirements.

Summarize:

Choice between vacuum casting and 3D printing depends on factors such as surface finish, quantity needed, customization, lead time, design complexity, and material requirements. In some cases, a combination of both methods may be the most suitable approach, with vacuum casting used for creating high-quality surface finish parts and 3D printing for complex or customized components.

Contact Tech Support in GD-HUB For Your Project Now