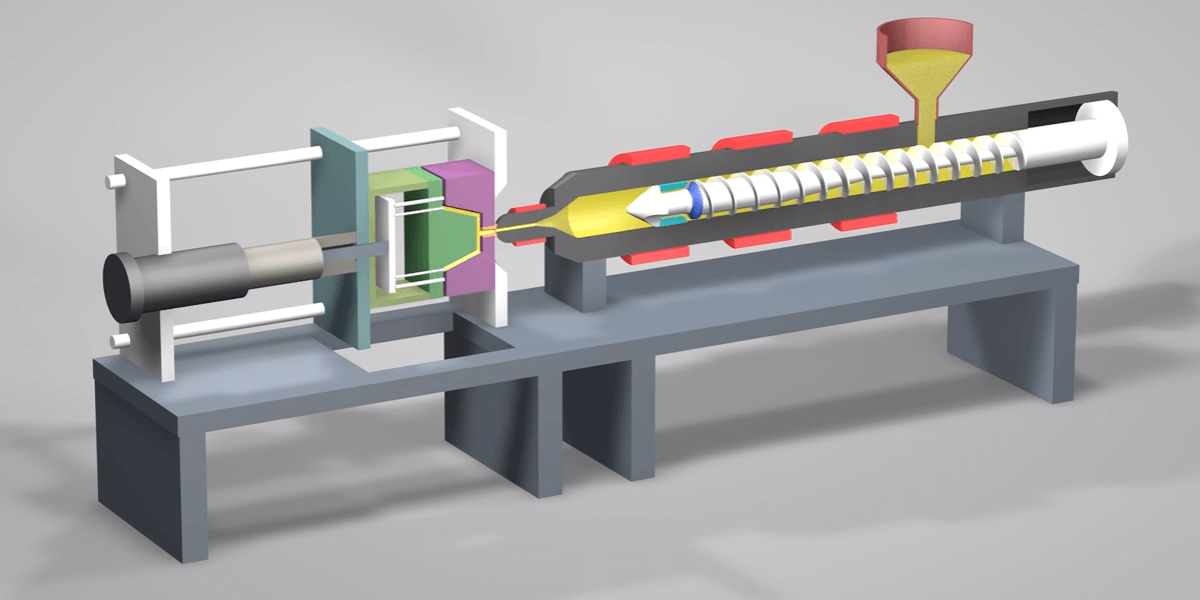

What is Injection molding?

Also known as plastic injection molding, the principle is to add granular or powdery raw materials into the hopper of the injection molding machine, the raw material is heated and melted into a flowing state, driven by the screw or piston of the injection molding machine, through the nozzle and the mold's pouring system into the mold cavity, and harden and set the shape in the mold cavity. Factors affecting the quality of injection molding: injection pressure, injection time, injection temperature.

The main advantage of injection molding is the ability to centralize and expand production. Once the machine and mold are ready, the price per unit of product is very low during production. As more parts are produced, the price drops dramatically.

Compared to traditional manufacturing processes such as machining, injection molding produces low scrap rates and can reduce a large percentage of the original blank or sheet. It may be slightly higher for additive manufacturing processes with relatively lower scrap rates for 3D printing. Scrap plastic in injection molding production typically comes from: the sprue, the location of the gate, and any overflow material that leaks from the part cavity.

Injection molding is a highly repeatable process. This means that the second part of production will be identical to the first part. This provides excellent control over product consistency and part reliability in high volume production.

What is Vacuum Casting?

Vacuum Casting is a process of making small quantities of products by pouring polyurethane materials into silicone molds. The material properties of the products are similar to engineering plastics, and the surface finish, color, product size and mechanical properties of the products obtained through vacuum injection molding can be similar to those of steel mold injection molded products. Vacuum Casting is the most ideal solution when 1-100 pieces of samples are needed, and the time and cost do not allow the direct opening of injection molds.

Rapid prototyping parts or other prototypes for the mother mold, the use of vacuum pouring silicone rubber method to produce high-strength silicone molds, this mold can be used for pouring engineering plastics, such as ABS, PP, PMMA, transparent PC and nylon, etc., in the absence of the need to open the case of steel molds, to achieve the small batch production of engineering plastics parts, the Vacuum Casting (Vacuum Casting machine) has the characteristics of fast pumping speed, high vacuum and easy to use reliable and so on. Vacuum Casting machine has the characteristics of fast pumping speed, high vacuum degree and convenient and reliable use.

Vacuum casting molding machine can be used for the rapid manufacture of silicone rubber molds, polyurethane molds, small batch injection moulding parts of the vacuum casting molding, widely used in automotive, home appliances, light industry, medical, agricultural machinery and military industries such as product development and small batch production.

How Injection Molding work:

Material Injection: Plastic pellets are melted and injected into a mold cavity under high pressure. The mold is typically made of metal and consists of two halves: the core and the cavity.

Cooling and Solidification: Once the molten plastic fills the mold, it is cooled and solidified by circulating coolant through the mold's channels. This ensures that the part takes on the desired shape and maintains its structural integrity.

Ejection: After the plastic has solidified, the mold is opened, and the finished part is ejected. The cycle then repeats for the next part.

Advantages of Injection Moulding:

High production efficiency: Suitable for large production runs due to fast cycle times.

High precision and repeatability: Produces parts with consistent dimensions and surface finish.

Wide material selection: Can use a variety of plastic materials with different properties.

Complex geometries: Can create intricate and detailed part designs.

Limitations of Injection Moulding:

High initial tooling cost: Creating the molds can be expensive, making it more suitable for larger production volumes.

Long lead times: Designing and fabricating molds can take time.

Limited for small runs: Not cost-effective for small quantities due to tooling costs.

Design constraints: Some part features may be challenging to mold due to mold design limitations.

How Vacuum Casting work:

Master Model: A master model (usually 3D printed or CNC machined) of the desired part is created. This master model serves as the basis for creating a mold.

Mold Making: A silicone mold is created around the master model. This mold captures all the intricate details of the part's surface.

Material Casting: Liquid polyurethane or other casting materials are poured into the mold. The mold is then placed in a vacuum chamber to remove air bubbles and ensure proper material flow.

Curing: The casting material cures and solidifies within the mold. The mold is then opened, and the finished part is removed.

Advantages of Vacuum Casting:

Quick turnaround: Faster than injection molding for creating prototypes and small runs.

Low-cost tooling: Creating silicone molds is less expensive than metal injection molds, making it viable for small-scale production.

Material variety: Different materials with varying properties can be used for casting.

Intricate details: Can reproduce fine details and textures from the master model.

Limitations of Vacuum Casting:

Limited production volume: Not suitable for large-scale production due to slower cycle times and mold wear.

Material limitations: Material options are more limited compared to injection molding.

Part geometry: Some complex geometries may be challenging to cast or require additional steps.

Surface finish: Surface finish may not be as consistent as injection molding.

Some considerations for injection molding:

1. Material Selection:

Choose the appropriate plastic material based on your part's intended use, mechanical properties, chemical resistance, and other requirements. There are various types of plastics available, each with its own characteristics.

2. Design for Injection Molding:

Design your part with injection molding in mind. Consider factors like wall thickness, draft angles, fillets, ribs, and undercuts to optimize the part for easy mold filling, ejection, and overall manufacturability.

3. Mold Design and Tooling:

The quality of the mold greatly influences the outcome of the injection molding process. Invest in high-quality mold design and construction to ensure consistent part quality, dimensional accuracy, and longevity of the mold.

4. Mold Material:

Select the appropriate mold material based on factors such as the number of cycles, material compatibility, and part complexity. Common mold materials include steel and aluminum.

5. Cooling System:

An efficient cooling system is crucial to maintain uniform part quality and minimize cycle times. Proper cooling channel design and placement help control the cooling process and reduce warping or stress in the parts.

6. Gate Design:

Choose the appropriate gate type and location for your part. The gate is where the molten plastic enters the mold cavity. The gate design affects the flow pattern, part appearance, and potential gate-related defects.

7. Injection Pressure and Speed:

Set the appropriate injection pressure and speed to ensure proper filling of the mold cavity. Balancing these parameters prevents issues like air traps, sink marks, and part deformation.

8. Injection Molding Machine Selection:

Select a molding machine that suits the size and complexity of your parts. Consider factors like clamping force, shot size, and automation capabilities.

9. Material Drying:

Some plastic materials are sensitive to moisture. Properly dry the plastic pellets before molding to prevent defects caused by moisture absorption.

10. Process Control and Monitoring:

Implement process control and monitoring systems to ensure consistency in part quality. Real-time monitoring can help identify issues early and prevent defects.

11. Post-Molding Operations:

Consider any required post-molding operations, such as trimming, painting, assembly, or packaging. These operations can impact the overall production process and costs.

Some considerations for vacuum casting

1. Material Selection:

Choose the appropriate casting material based on the desired mechanical, thermal, and aesthetic properties of the final part. Different polyurethane formulations offer varying levels of hardness, flexibility, transparency, and color options.

2. Master Model Preparation:

Create a high-quality master model with the desired part geometry and surface finish. The master model serves as the basis for creating the mold, so any imperfections or inaccuracies in the master will be transferred to the final parts.

3. Mold Design and Manufacturing:

Design the silicone mold to accurately capture all the details and features of the master model. Ensure that undercuts and complex geometries can be demolded successfully. Choose appropriate mold-making materials and techniques to achieve durability and repeatability.

4. Mold Release Agents:

Use suitable mold release agents to prevent the casting material from adhering to the mold surfaces. Proper application of release agents ensures easy part removal and extends the life of the mold.

5. Vacuum Degassing:

Vacuum degassing is a critical step to remove air bubbles from the casting material before it cures. Proper degassing minimizes defects in the finished parts and ensures consistent material properties.

6. Material Mixing and Dispensing:

Accurate mixing and dispensing of the casting material are crucial to achieve consistent material properties across multiple parts. Follow the manufacturer's guidelines for mixing ratios and curing times.

7. Color and Aesthetics:

If color is important for your parts, consider pigmenting the casting material to achieve the desired appearance. Keep in mind that certain pigments or additives might affect material properties.

8. Part Orientation and Placement:

When placing the master model within the mold, consider how the casting material will flow and fill the mold cavity. Proper orientation and positioning can help minimize material waste and ensure uniform material distribution.

9. Production Volume and Lead Time:

Understand the limitations of vacuum casting in terms of production volume and cycle times. This process is better suited for small to medium production runs and quick turnaround times compared to injection molding.

Different and same of vacuum casting & injection moulding

Differences:

Production Volume:

Vacuum Casting: Primarily suited for small to medium production runs and prototyping due to slower cycle times and mold wear limitations.

Injection Molding: Well-suited for high-volume production due to faster cycle times and the ability to maintain consistency over long runs.

Tooling Costs:

Vacuum Casting: Generally has lower initial tooling costs since silicone molds are less expensive to produce compared to metal injection molds used in injection molding.

Injection Molding: Requires higher initial investment in tooling, making it more economical for larger production volumes.

Lead Times:

Vacuum Casting: Offers quicker turnaround times for producing prototypes and small batches since mold creation is less complex and time-consuming.

Injection Molding: Involves longer lead times due to the design and fabrication of complex metal molds.

Material Selection:

Vacuum Casting: Offers a limited range of casting materials, typically polyurethane-based, with varying hardness and properties.

Injection Molding: Provides a wider selection of plastic materials with diverse properties such as strength, flexibility, heat resistance, and more.

Complexity and Detail:

Vacuum Casting: Capable of reproducing intricate details and textures from the master model, making it suitable for parts with fine aesthetics.

Injection Molding: Can handle complex part geometries and features with high precision and consistency.

Similarities:

Prototyping:

Both processes are used for prototyping to validate designs, test functionality, and identify any potential issues before committing to mass production.

Material Properties:

Both processes allow for tailoring material properties to suit specific requirements. This includes selecting materials with the desired mechanical, thermal, and aesthetic characteristics.

Tooling Design:

Both processes involve the design and creation of molds, although the complexity and material of the molds differ. Proper mold design is crucial for both processes to ensure successful production.

Material Waste:

Both processes can generate material waste during setup, purging, and potential defects. Proper process optimization can help minimize waste in both cases.

Part Quality Control:

Quality control measures are important in both processes to ensure that the final parts meet the desired specifications. Inspection and testing are common practices.

Post-Processing:

Both processes might require post-processing steps such as trimming, painting, assembling, and finishing to achieve the desired final appearance and functionality.

Vacuum Casting Applications:

Prototyping: Vacuum casting is often used for creating functional prototypes that closely mimic the properties of the final product. This is especially useful for testing fit, form, and function before committing to mass production.

Small Batch Production: Vacuum casting is suitable for producing small quantities of parts that require specific material properties or aesthetics, such as consumer electronics, medical devices, and automotive components.

Customized Products: Industries like consumer goods and fashion often utilize vacuum casting to create custom or personalized products with unique textures, colors, and surface finishes.

Design Validation: Designers can use vacuum-cast prototypes to validate design concepts, make adjustments, and gather feedback before moving to injection molding for higher volumes.

Art and Sculpture: Vacuum casting can be used to reproduce intricate artistic sculptures, decorative elements, and art pieces that require precise replication of details and textures.

Injection Moulding Applications:

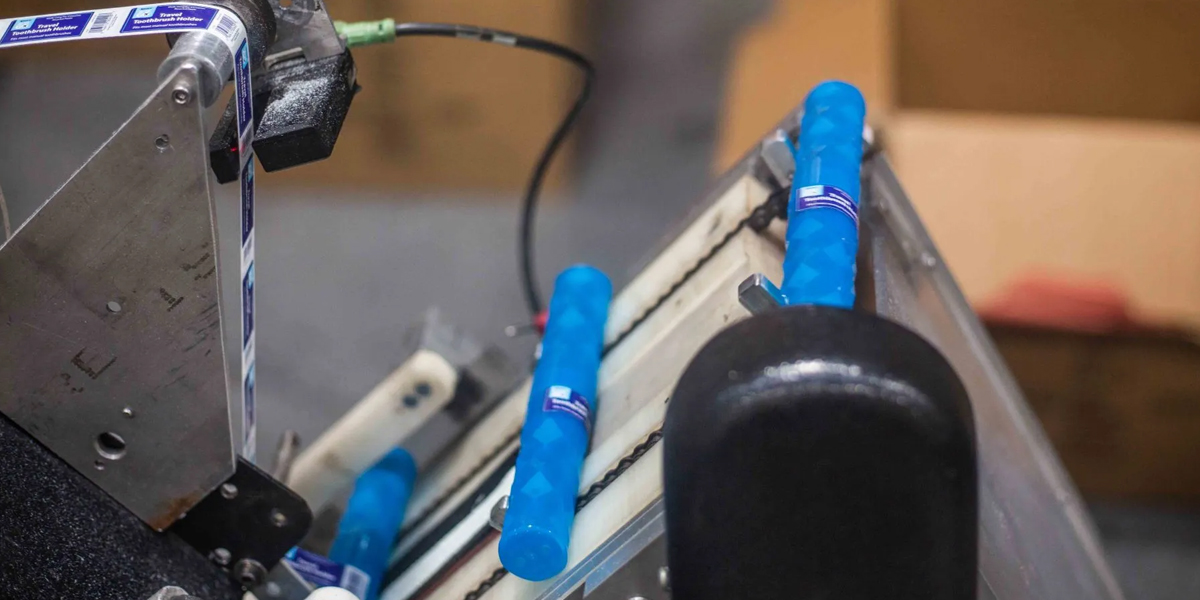

Mass Production: Injection molding is ideal for high-volume manufacturing of plastic parts, such as packaging, consumer goods, toys, and automotive components.

Consumer Electronics: Many components of electronic devices, including casings, connectors, and buttons, are manufactured using injection molding due to its speed and precision.

Medical Devices: Injection molding produces medical instruments, device housings, and disposable items with strict quality control and consistency requirements.

Automotive Industry:Injection molding is widely used for producing various components in vehicles, including interior trim, exterior parts, engine components, and dashboard elements.

Household Appliances: Injection molding is applied to create components for appliances like kitchen gadgets, home entertainment systems, and household items.

Construction: Injection-molded parts are used in construction for items such as pipes, fittings, insulation, and structural elements due to their durability and cost-effectiveness.

Industrial Tools and Equipment: Many industrial tools and equipment parts are made through injection molding for their mechanical properties and resistance to harsh environments.

Vacuum casting is often chosen for prototyping, small batch production, and creating parts with unique aesthetics or material properties. Injection molding is favored for high-volume production of standardized parts across various industries, where speed, efficiency, and consistent quality are critical.

Consult GD-HUB for the best solution.