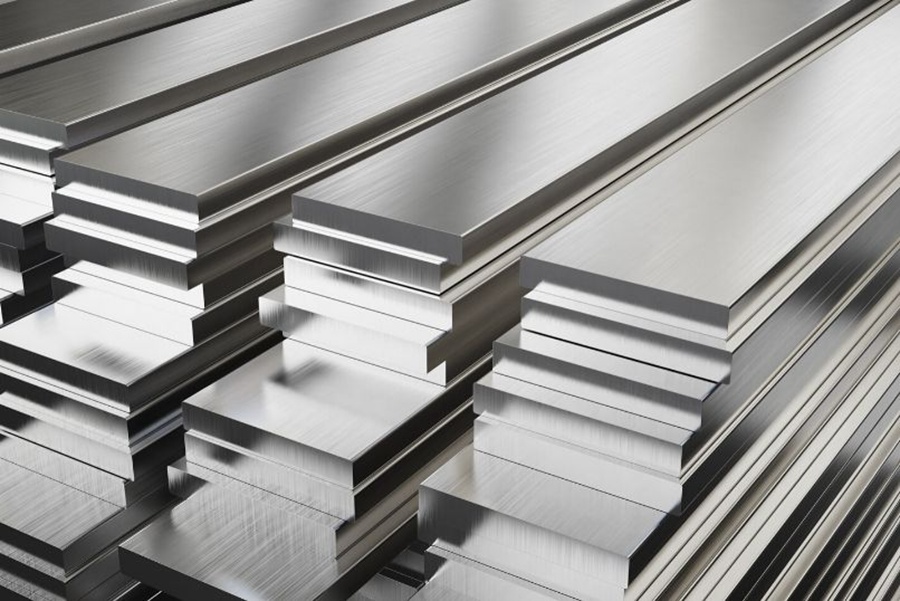

Aluminum

Aluminum 6061-T6 | 3.3211| 65028| AlMg1SiCu

Aluminum 6061 (CNC) is the most popular aluminum alloy. It has good strength-to-weight ratio, excellent machinability and natural corrosion resistance.

Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCu

Aluminum 7075-T6 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels.

Aluminum 6060 | 3.3206 | AlMgSi

Alloy 6060 offers good strength, relatively good corrosion resistance and is suitable for decorative anodizing.

Aluminum 6060 | 3.3206 | AlMgSi

Alloy 6060 offers good strength, relatively good corrosion resistance and is suitable for decorative anodizing.

Aluminum 5083-H111 | 3.3547 | 54300| AlMg4.5Mn0.7

Aluminum 5083 (CNC) is a strain hardening aluminum alloy with excellent corrosion resistance. Suitable for marine applications. Can be welded.

Aluminum 6063 | EN AW-6063 | 62400| AlMg0,7Si

Aluminum 6063 has good mechanical properties and can be heat treated. Suitable for aerospace applications. Can be welded.

Aluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5

Aluminum 5052 is a strain hardening aluminum alloy with excellent corrosion resistance. Suitable for marine applications. Can be welded.

Aluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5

Aluminum 5052 is a strain hardening aluminum alloy with excellent corrosion resistance. Suitable for marine applications. Can be welded.

Aluminum 7050 | EN AW-7050 | 3.4144| AlZn6CuMgZr

Aluminum 7050 has excellent mechanical properties with good ductility, high strength, toughness and good resistance to fatigue. Suitable for aerospace applications.

Aluminum MIC6

Aluminum MIC6 is a light weight material that can be easily machined at high speed and is free from tension, contaminants and porosity.

Aluminum 6082-T651 | 3.2315 | 64430 | AlSi1MgMn

Aluminum 6082-T65 (CNC) has very similar composition and properties to 6061, with slightly higher tensile strength. Compliant with British Standards.

Aluminum 2017 | 3.1325 | 24530 | AlCu4MgSi

Aluminum 2017 has a higher ductility and formability than Aluminum 2014 and has intermediate strength.

Aluminum 2017 | 3.1325 | 24530 | AlCu4MgSi

Aluminum 2017 has a higher ductility and formability than Aluminum 2014 and has intermediate strength.

Aluminum 2014 | 3.1255 | 24345 | AlCu4SiMg

Aluminum 2014 is easily machined and can be hardened to get strengths comparable to steel, but is prone to corrosion. Suitable for aerospace applications.

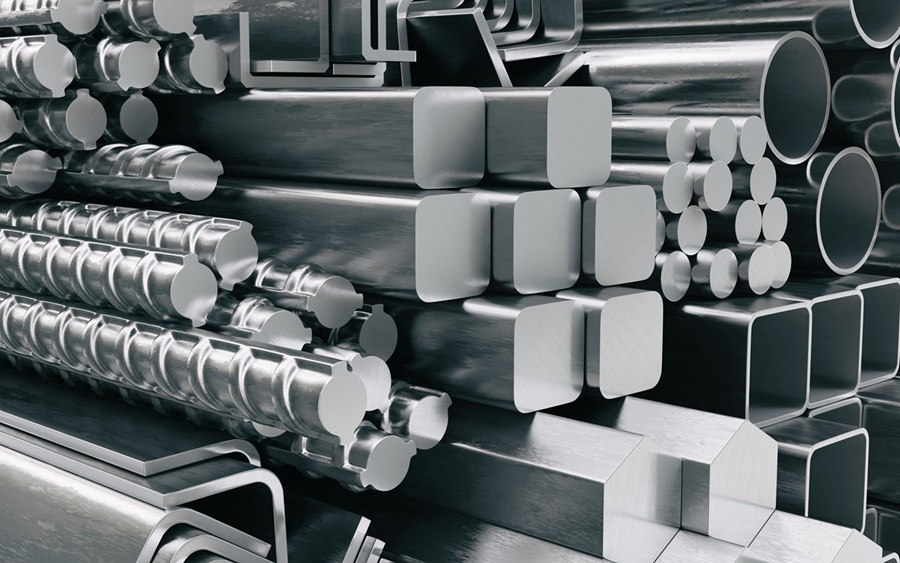

Stainless steel

Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9

Stainless steel 304L (CNC) has excellent mechanical properties and good machinability. Resistant to most environments and corrosive media.

Stainless steel 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2

Stainless steel 316L (CNC) has similar mechanical properties to 304, with higher corrosion and chemical resistance. Ideal for marine applications.

Stainless steel 303 | 1.4305 | X8CrNiS18-9

Stainless steel 303 (CNC) has excellent toughness, but lower corrosion resistance than 304. Ideal for high volumes, due to its excellent machinability.

Stainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4

Stainless steel 17-4 (CNC) - SAE grade 630 - is a precipitation hardening alloy with good corrosion resistance. Can be hardened up to 44 HRC.

Stainless steel 416 | 1.4005 | X12CrS13

Stainless steel 416 is magnetic and has a high machinability.

Stainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3

Stainless steel 2205 Duplex (CNC) is the alloy with the highest strength and hardness. Suitable for applications in severe environments up to 300°C.

Stainless steel 420 | 1.4028 | X30Cr13

Stainless steel 420 provides high strength and corrosion resistance. It is the hardest of all stainless steels when hardened.

Stainless steel 440C | 1.4125 | X105CrMo17

Stainless steel 440C has improved toughness and corrosion resistance due to Carbon and Chromium content.

Stainless steel 430 | 1.4016 | X6Cr17

Stainless steel 430 is magnetic and corrosion resistant.

Stainless steel 301 | 1.4310 | X10CrNi18-8

Stainless steel 301 is corrosion resistant similar to Stainless steel 304.

Stainless steel 15-5 | 1.4545 | FE-PM1802 | X5CrNiCu15-5

Stainless steel 15-5 has a higher toughness than 17-4, better corrosion resistance and transverse properties compared to other similar martensitic grades.

Mild steel

Mild steel 1018 | 1.1147 | C18 |16Mn

Mild steel 1018 (CNC) is a general-use alloy with good machinability, weldability, toughness, strength. Susceptible to corrosion.

Carbon steel EN8/C45 | 1.0503 | 1045H | Fe

C45 has low thermal conductivity and low ductility among wrought carbon steels.

Mild steel S355J2 | 1.0577 | 1522H | Fe 510 D

S355J2 has a high tensile strength. Compared to other carbon steels, it has high electrical conductivity but low thermal conductivity and low ductility.

Mild steel 1045 | 1.1191 | C45E | C50

Mild steel 1045 (CNC) is a medium carbon steel with good weldability and machinability, high strength and good impact resistance. Susceptible to corrosion.

Mild Steel S235JR | 1.0038 | Fe 360 B

S235JR is a hot rolled non-alloy structural steel. It has good plasticity, toughness and weldability, certain strength and good cold bending properties.

Mild steel A36 | 1.025 | Fe 410 | IS2062

Mild steel A36 (CNC) is a common structural steel with good weldability. Suitable for a variety of industrial applications. Susceptible to corrosion.

Mild steel S275JR | 1.0044 | 1518 | Fe430B

As a low carbon steel specifications S275 provides low strength with good machinability and is suitable for welding

Brass

Brass Cz121 | C38500 | 2.0401 | CuZn39Pb3

Brass Cz121/C360 (CNC) is a highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

Brass C360 (CNC) is highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

Copper

Copper C110 | CU ETP

Copper (C110) is a pure at 99.90% copper alloy, with universal for electrical applications high thermal conductivity and good corrosion resistance.

Copper C101 | CU OFE

Copper (C101), 99.99% pure, is a copper alloy with excellent conductivity and high corrosion resistance and toughness.

Alloy steel

Alloy steel 1.7131 | 16MnCr5

Steel 1.7131 has a high surface hardness and wear resistance with good machinability.

Alloy steel 4140 | 1.2331 | EN19 | 42CrMo

Alloy steel 4140 (CNC) has good overall properties, with good strength and toughness. Suitable for many industrial applications. Not weldable.

Alloy steel 1.7225 | 42CrMo4

Steel 1.7225 has high strength, toughness, good hardenability and good resistance to impact.

Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24

Alloy steel 4340 (CNC) can be heat treated to high strength, while maintaining good toughness, wear resistance and fatigue strength. Weldable.

Alloy steel 1215 | EN1A | 1.0715

Alloy steel 1215 is a low tensile, low harden-ability carbon steel. Can be machined at higher speeds.

Tool steel

Tool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Tool steel D2 (CNC) is a wear-resistant alloy that retains its hardness to a temperature of 425 °C. Used for cutting tools and dies.

Tool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state

Tool steel A2 (CNC) is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Tool steel O1 | 1.2510 | 100MnCrW4 - Annealed state

Tool steel O1 (CNC) is an oil-hardened alloy with a high hardness of 65 HRC. Used for industrial knives and cutting tools.

Tool steel A3 - Annealed state

Tool steel A3 is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Tool steel S7 | 1.2355 | 50CrMoV13-15 - Annealed state

Tool steel s7 has very high impact properties. Suitable for tool and die application..

Tool steel H13 | 1.2344 | X40CrMoV5-1 - Annealed state

Tool steel H13 has an excellent combination of high toughness and fatigure resistance. It is the most common tool steel used in tooling applications.

Titanium

Titanium Grade 5 | 3.7164 | Ti6Al4V

Stronger than Grade 2, equally corrosion-resistant, and excellent bio-compatibility.

Titanium Grade 2 | 3.7035

Stronger than Grade 1 and equally corrosion-resistant, excellent bio-compatibility.

Titanium Grade 1 | 3.7025

Titanium Grade 1 (CNC) is a commercially pure metal with excellent corrosion and impact resistance and good machine ability and weld ability.

Inconel

Inconel 718

Inconel 718 is a high-strength, corrosion-resistant nickel alloy.

Invar

INVAR is a nickel alloy with a very low coefficient of thermal expansion.

Plastics

POM

Acetal Copolymer (POM-C)

Acetal (POM-C) is the easiest to machine engineering plastic. Ideal for parts with high stiffness, low friction and very low water absorption.

Acetal Copolymer (POM-C) FDA

Acetal is an engineering thermoplastic used in precision parts requiring high stiffness, low friction and excellent dimensional stability

Acetal Homopolymer (POM-H)

Delrin (POM-H) is the easiest to machine engineering plastic. Ideal for parts with high stiffness, low friction and very low water absorption.

Acetal Copolymer (POM-C) ESD

Semicrystalline engineering plastic, permanently antistatic for varied applications in electronics,clean rooms and safety areas.

Nylon(PA)

Nylon 6

Nylon 6 (CNC) - PA 6 - has excellent mechanical properties, with high toughness and hardness. Susceptible to moisture absorption.

Nylon 6 30% Glass Filled

Glass-reinforced nylon has higher tensile strength than un-reinforced nylon while still benifitting from its flexibility. Very tough.

Nylon 6/6 30% Glass Filled

This grade has been re-enforced with glass fibres - and the composite inherits good strength, hardness and abrasion resistance from the 30% glass filler, and tough and lightweight properties of the plastic.

Nylon 6 Flame Retardant

PA 6 FR possesses a high degree of stiffness, tensile strength as well as good sliding and wear properties with simultaneously outstanding corrosion and chemical resistance.

PPSU

PPSU | UL94 V-0

PPSU offers hydrolytic stability, toughness and superior impact strength over a wide temperature range.

ABS

ABS

ABS (CNC) has good mechanical properties and excellent impact resistance. It is commonly used to prototype parts prior to injection-molding.

PEEK

PEEK

PEEK (CNC) is an engineering thermoplastic with excellent mechanical and thermal properties. Can be used to replace metal parts. Biocompatible.

PTFE (Teflon)

PTFE

Teflon (CNC) - PTFE - has excellent thermal and chemical resistance and outstanding frictional and electrical properties.

Polycarbonate

PC

Polycarbonate (CNC) has excellent impact strength and good temperature resistance. Suitable for outdoor applications. Can be colored or semi-transparent.

Polyethylene

HDPE

HDPE (CNC) is a lightweight and strong thermoplastic, suitable for outdoor applciations. Commonly used for prototypes before Injection Molding.

UHMW-PE

High density polyethylene is very tough due to its long chain structure and has the highest impact strength of any thermoplastic.

PVC

PVC

PVC is the third most used plastic with all-around good mechanical properties, excellent chemical and weather resistance and good toughness.

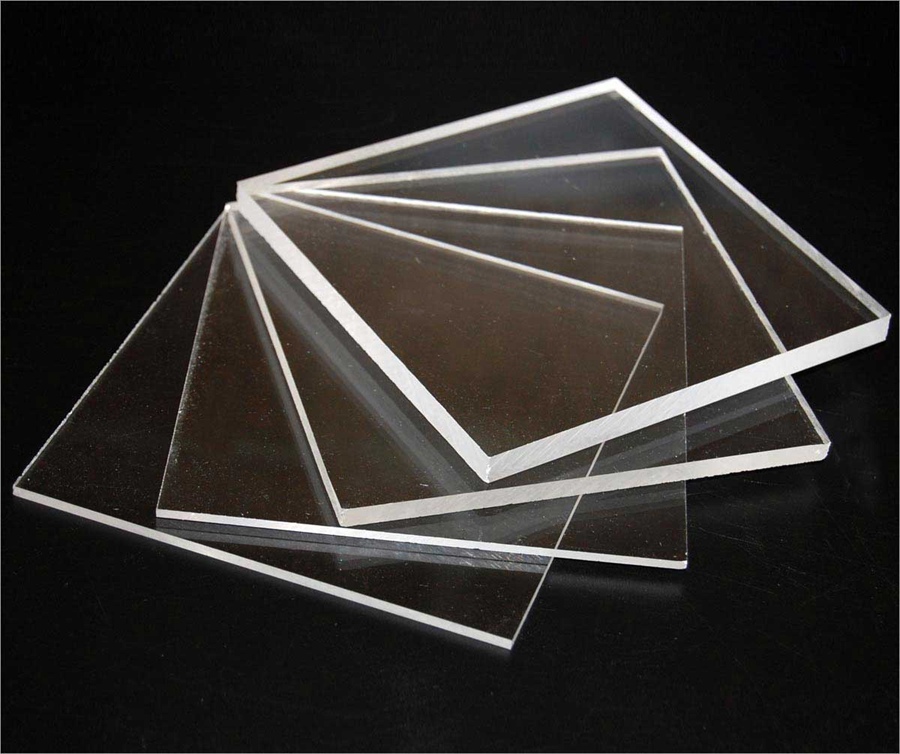

PMMA (Acrylic)

PMMA (Acrylic)

PMMA is a translucent rigid plastic, often used as a substitute for glass and when high transparency is needed, a high polishing process can be done to achieve this.

PET

PET

PET is a tough plastic that offers excellent wear resistance and mechanical strength.

Polypropylene

PP Homopolymer

PP-H offers a high strength to weight ratio and is stiffer and stronger than copolymer, this combined with good chemical resistance and weldability allows this material to be used in many corrosion resistant structures.

PP

Polyproplene has similar properties to polyethylene but is harder and more heat resistant.

PP+GF(30%)

Reinforced polypropylene with glass fiber for improved tensile strength.

Related Knowledge