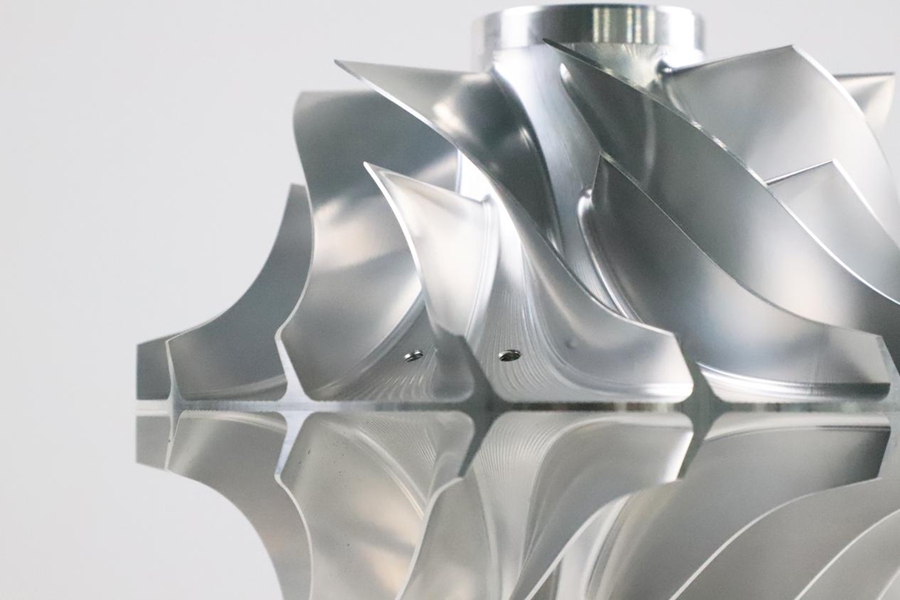

Impeller is a important component used in automotive systems such as engines, turbochargers, and superchargers.

GD-HUB has produced many of these precision parts, these precision parts involve 5-axis CNC machining.

In an engine, the impeller is a rotating component that is usually located within the water pump. It helps to circulate the engine coolant by creating a centrifugal force that moves the liquid through the cooling system.

In a turbocharger or supercharger, the impeller is a wheel with blades that compresses the air flowing into the engine.

GD-HUB's CNC machining center is equipped with 150+ advanced CNC machining machines and a large team of CNC technicians, including CNC machine operators, CNC programmers, and solution designers.

We use 5-axis CNC machining for many automotive companies to make the precision parts they need. This impeller is one of the precision parts produced on our CNC center.

Our 5-axis CNC machining typically used for manufacturing precise, complex shapes and parts. GD-HUB's 5-axis CNC machining typically service in industries such as:

Aerospace industry: The aerospace industry often uses 5-axis CNC machining to manufacture complex parts for aircraft engines, turbines, and other components. These parts require high precision and accuracy, and 5-axis machining allows for the creation of complex shapes and curves that would be difficult to achieve with traditional machining methods.

Automotive industry: 5-axis CNC machining is also commonly used in the automotive industry for the production of engine blocks, cylinder heads, and other critical components. The ability to produce complex shapes with high accuracy and speed makes 5-axis machining a popular choice for automotive manufacturers.

Medical device industry: Medical device manufacturers often use 5-axis CNC machining to produce complex components such as prosthetics, implants, and surgical instruments. The high precision and accuracy of 5-axis machining ensure that these parts are manufactured to exact specifications, which is critical for their safe and effective use in medical applications.

Mold and die making: 5-axis CNC machining is also widely used in mold and die making, where complex shapes and contours are required to create injection-molded parts or stamped metal components. The ability to create intricate shapes quickly and accurately makes 5-axis machining an ideal choice for this type of application.

Prototyping: 5-axis CNC machining is often used for rapid prototyping and the production of one-off or small-batch parts. The ability to quickly produce complex shapes and designs makes 5-axis machining an ideal choice for prototyping and product development.

Related Knowledge