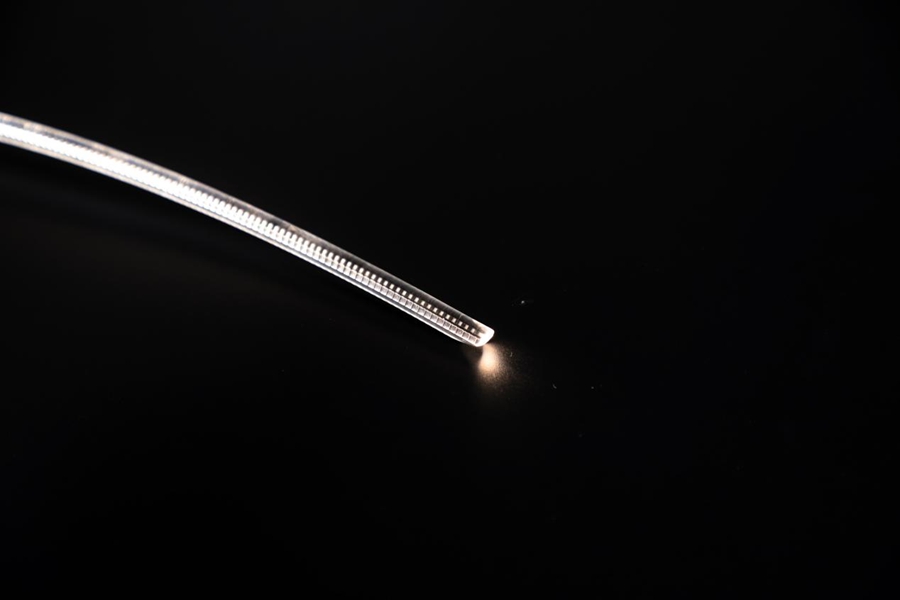

A Light Guide Strip is a type of lighting technology that is commonly used in modern automotive headlights. It is a strip of light that is usually located on the outer edge of the headlight assembly and is designed to provide a distinctive visual appearance while also improving visibility.

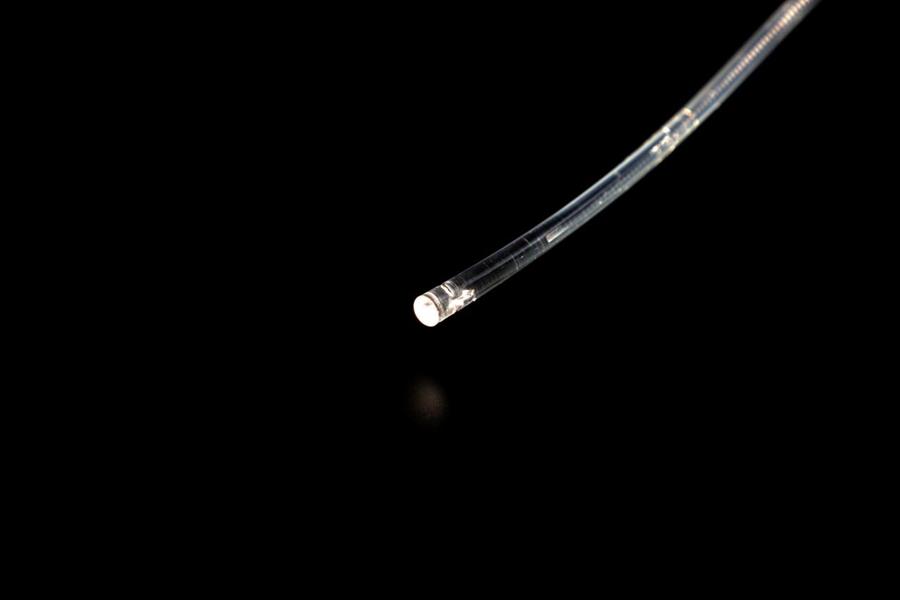

The Light Guide Strip is typically made of a clear or frosted plastic material that is illuminated by LED lights. The LEDs are mounted at one end of the Light Guide Strip and emit light that is transmitted through the bar to the other end, where it is dispersed evenly across the surface of the bar. This creates a uniform and continuous strip of light that is visible to other drivers on the road.

The primary benefits of using a Light Guide Strip in automotive headlights include improved visibility, enhanced safety, and a unique aesthetic appeal. The even distribution of light across the bar helps to reduce glare and provide better illumination of the road ahead, while also making the vehicle more visible to other drivers.

Production process of Light Guide Strip

1. Material selection: The first step in the production process is selecting the materials for the light guide strips. Common materials used for light guide strips include polycarbonate, acrylic, and polyurethane.

2. Extrusion: After selecting the materials, the next step is to extrude the material into the desired shape of the light guide strip. GD-HUB using an extruder machine, which heats and melts the material and then pushes it through a die to create the desired shape.

3. Cooling: Once the extrusion process is complete, the light guide strip needs to be cooled to harden the material and retain its shape.

4. Cutting: After the light guide strip has cooled and hardened, we needs to be cut to the desired length.

5. Surface treatment: The surface of the light guide strip may need to be treated to improve its optical properties. Our experienced surface finishing team did a good job of surface finishing and performance testing of all the parts.

Throughout the production process, it is important to maintain clean and controlled production conditions to ensure the quality of the light guide strip. GD-HUB had cooperated with a well-known automobile company to produce this part. From material selection to final finishing treatment, GD-HUB perfectly completed this cooperation for Light Guide Strip production.

Related Knowledge